What is a non-contact infrared thermometer pyrometer used for?

Non-contact infrared pyrometers are used in various areas: in everyday life (measuring body temperature, food, batteries, floors), in construction, in heat and power engineering, in laboratory research, in industry and at enterprises where it is important to quickly and, most importantly, safely measure objects with very high temperatures. They can also be used to measure the temperature of moving mechanisms and parts (for example, in a car).

What types of non-contact thermometers are there?

There are two types of infrared thermometers: for measuring human temperature and for household/industrial use.

Infrared thermometers for people have a narrow range of measured temperatures (from 34 to 42 degrees Celsius), due to which they can give accurate temperature readings (permissible error of 0.1-0.3 degrees Celsius), which is very important when measuring human body temperature. Pyrometers for people are popular because they allow you to measure the temperature instantly, which is very convenient for both the person whose temperature is being measured (especially if the temperature needs to be measured for a child) and for the attending (especially if the temperature needs to be measured constantly for several people). In order to correctly measure a person's temperature, you need to bring the pyrometer to the forehead at a distance of 1-2 cm. With this measurement, the data will be as accurate as possible.

Industrial non-contact infrared thermometers have a wide range of measured temperatures, but the error is too high to be used to measure the temperature of people.

How to use household/industrial pyrometers correctly?

There are several simple rules, if followed, which will ensure that the pyrometer readings are as accurate as possible:

1. It is necessary to take into account the material of the measured object (radiation coefficient).

The emissivity coefficient (emission coefficient) of different materials is different. Therefore, when measuring the temperature of different materials, it is necessary to set the appropriate emissivity coefficient. Most organic and colored/oxidized materials have an emissivity coefficient close to 0.95. Pyrometers that do not have an emissivity coefficient adjustment function are always set to 0.95, i.e. they are suitable for household use. Pyrometers with an emissivity coefficient adjustment function are universal, as they are suitable for measuring the temperature of any materials with different temperatures and different degrees of roughness.

If you want a truly universal pyrometer, we recommend that you definitely take a model with an adjustable emissivity coefficient and a wide range of measured temperatures. The most popular and universal pyrometers with such functionality are the models GM550 And GM900. It should be remembered that the emissivity of the same materials may vary depending on the temperature and the smoothness/roughness of the surface. To minimize the error in temperature measurement, refer to the table below.

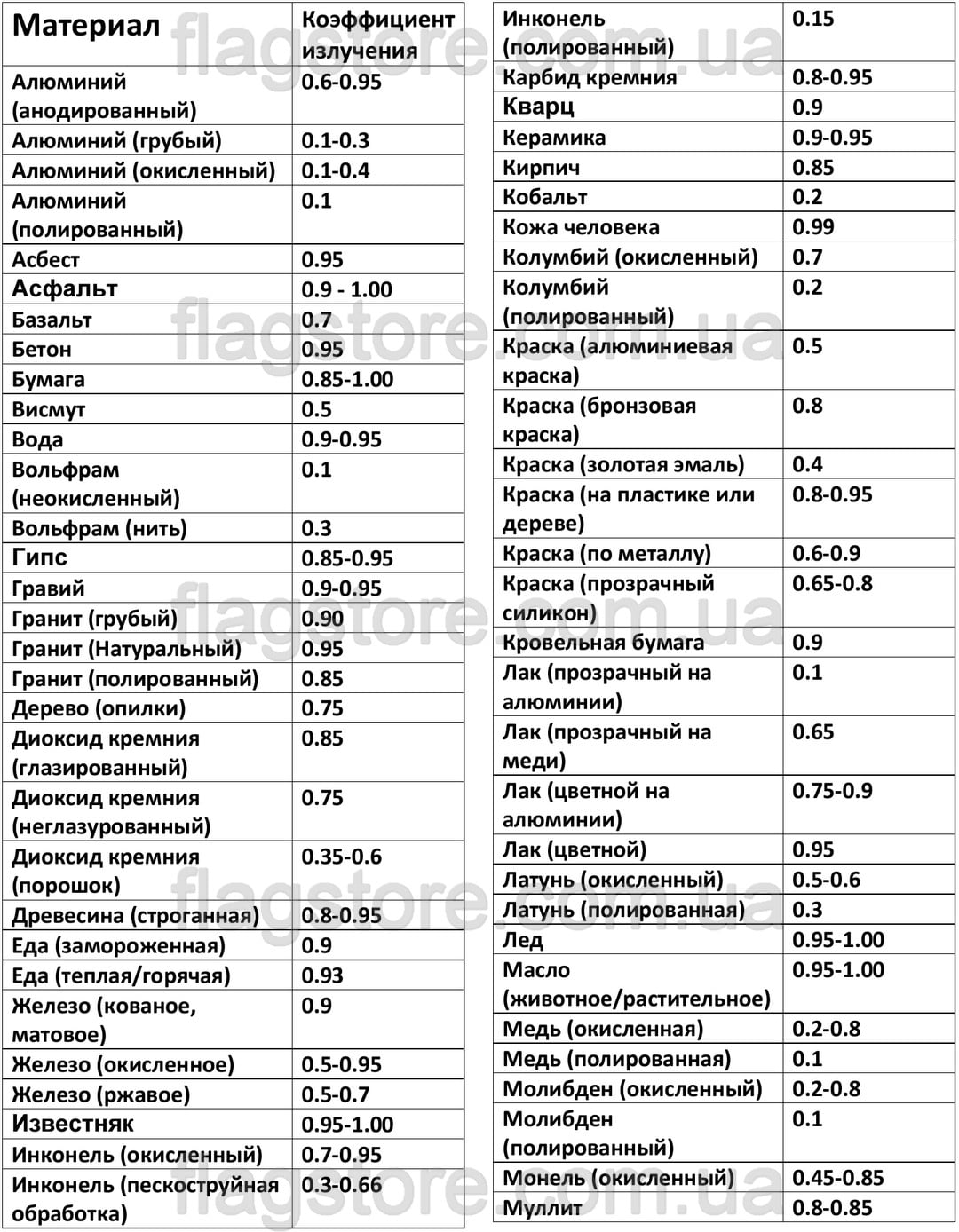

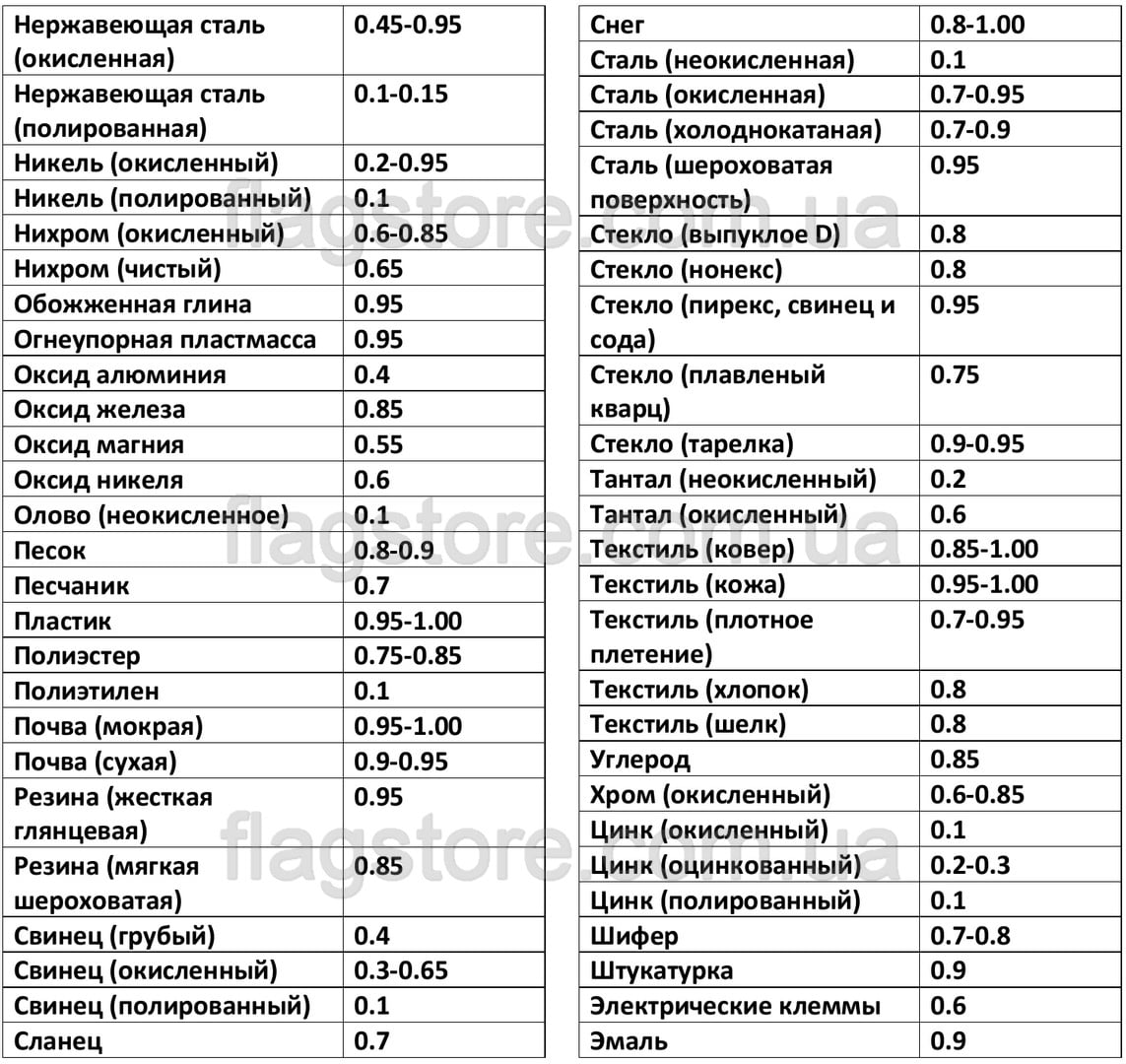

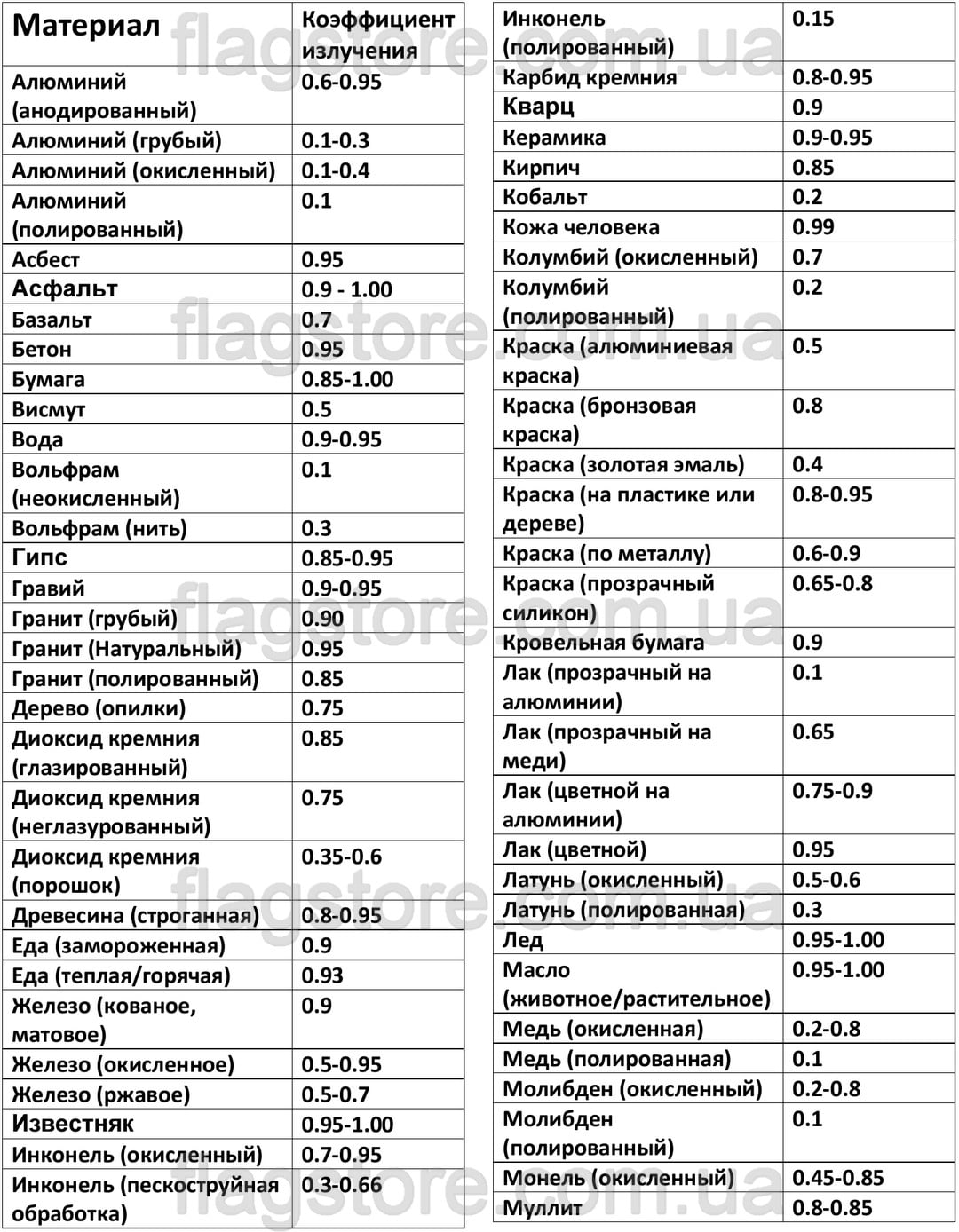

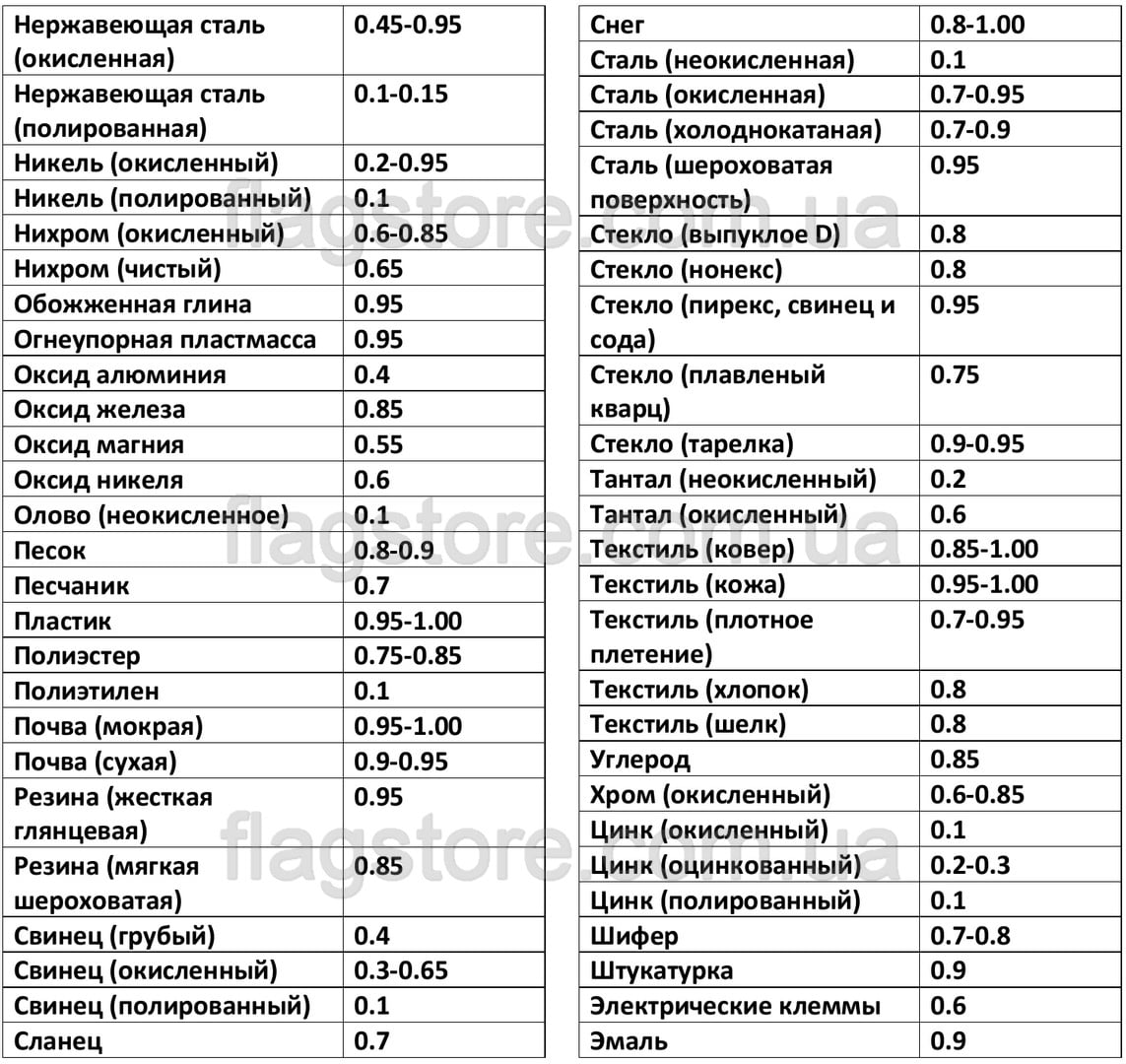

Table of emissivity coefficients of materials at temperatures from 0 to 250 degrees Celsius (in alphabetical order):

What should you do if you need to measure the temperature of a material that is not in the table above or you do not know what material the object is made of? The solution is very simple. You simply place the material whose emission coefficient you know on the object to be measured. For example, regular electrical tape: stick the tape on, wait a couple of minutes until it and the object of measurement reach temperature equilibrium, and with the emissivity coefficient set to 0.95, measure the temperature of the tape (with which you will find out the temperature of the material itself).

2. It is necessary to take into account the distance from the non-contact thermometer to the measured object, taking into account the optical resolution of the pyrometer.

Pyrometers have a laser pointer, but they measure the temperature not of the pointer itself, but of a larger round spot. The greater the distance between the pyrometer and the object being measured, the larger the diameter of the circle from which the pyrometer reads the temperature. It is important that the object whose temperature needs to be measured is within the round spot. If another object falls within the circle, the pyrometer will give an incorrect temperature value. That is, the closer you bring the pyrometer to the object being measured, the more accurate the readings will be.

How to determine the size of the round spot? It depends on the optical resolution of the pyrometer and the distance to the object of measurement. The higher the optical resolution of the pyrometer, the smaller the spot will be. Typically, the optical resolution is 12 to 1. As a rule, the changes in the size of the measured circle depending on the distance are illustrated on the side of the pyrometer. As on the GM900 pyrometer:

From the illustration we see that from a distance of 30 cm we will have a spot with a diameter of 38 mm (3.8 cm); from a distance of 90 cm the spot will be 75 mm (7.5 cm), and from a distance of 150 cm (1.5 meters) the spot will be 132 mm (13.2 cm).

If the object of measurement is small and is located next to other objects, then the closer we bring the pyrometer to the object of measurement, the more accurate the temperature readings will be.

3. It is necessary to remove all obstacles between the pyrometer and the measured object.

A pyrometer cannot measure the temperature of an object that is behind glass, dust, steam, smoke, transparent plastic. Since all of this (glass, dust, steam, smoke, plastic and other substances) have their own temperature and, accordingly, their own radiation. That is, when you measure the temperature of an object behind glass, the pyrometer will show you the temperature of the glass, and not the object behind it. Before measuring the temperature, be sure to remove all obstacles.

4. The air temperature and the temperature of the pyrometer itself should be approximately the same.

If you need to measure the temperature of an object that is outside a warm room or in a cold room (basement, garage), then for an accurate temperature measurement you need to wait 15-20 minutes so that the temperature of the pyrometer and the ambient air temperature become approximately the same. Then the error of the pyrometer will be minimal.

5. At what angle should you “shoot” and the background of the object

— For the most accurate temperature measurement, the pyrometer must be positioned perpendicular to the measured surface (this rule especially applies to objects with an emissivity lower than 0.9). For objects with an emissivity higher than 0.9, the maximum permissible deviation from the perpendicular is 30 degrees.

— When measuring translucent objects (plastic, glass), make sure that the background is uniform and has the same or lower temperature than the measured object.

If all these rules are followed, the temperature measurement results will be as accurate as possible.

Where to buy a pyrometer (infrared thermometer) in Kyiv and Ukraine?

You can pick up the infrared thermometer from our warehouse in Kyiv on the day of the order. There is also the option of sending by Nova Poshta: shipments are made daily - this means that you can receive the goods the next day after placing the order, provided that you are in large cities such as Kyiv, Odessa, Dnipro, Chernigov, Kharkov, Nikolaev, Zaporozhye, Lviv, Uzhgorod, Lutsk, Vinnytsia, Zhitomir, Ivano-Frankivsk, Kropyvnytskyi, Poltava, Ternopil, Sumy, Kherson, Chernivtsi, Rivne, Khmelnitsky, Cherkassy, Krivoy Rog, Mariupol, Kamenskoye, Kremenchuk, Bila Tserkva, Kramatorsk, Melitopol, Slavyansk and other large cities of Ukraine.